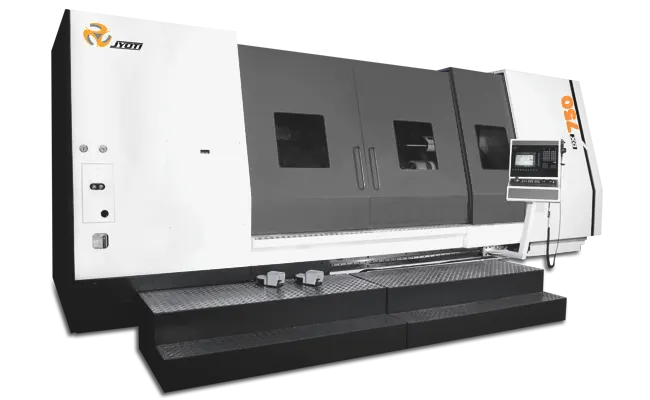

DX

Key Features

- Single piece slant saddle construction.

- Rigid and durable structure for hard part turning.

- Powerful high torque spindle with rigid headstock.

- Wider liner motion type guide ways.

- Step-up construction for vibration free heavy cutting.

- Heavy duty – high precise bi-directional servo turret.

- Live tool turret option available for milling operations.

- Ergonomically design concept.

- Efficient chip disposal.

- Tail stock with hydraulic quill.

- Hydraulic chucking.

- Auto and manual coolant system.

- Electrical with quality devices & panel with A.C.

- Centralized & programmable lubrication.

- Monoblock Structure

- Step-up Structure

- 3-point Leveling

- Bi-directional servo turret

| DX 500 - 1000 A | DX 500 - 1000 B | DX 500 - 1000 C | DX 500 - 1250 A | DX 500 - 1250 B | DX 500 - 1250 C | DX 500 - 2000 A | DX 500 - 2000 B | DX 500 - 2000 C | DX 750 - 1250 A | DX 750 - 1250 B | DX 750 - 3000 A | DX 750 - 3000 B | ||

| Capacity | ||||||||||||||

| Swing Over Bed | mm | 800 | 800 | 800 | 825 | 825 | 825 | 825 | 825 | 825 | 1050 | 1050 | 1050 | 1050 |

| Std. Turning Dia. | mm | 550 | 550 | 550 | 600 | 600 | 600 | 600 | 600 | 600 | 780 | 780 | 780 | 780 |

| Max. Turning Dia.* | mm | 700 | 700 | 700 | 800 | 800 | 800 | 800 | 800 | 800 | 920 | 920 | 920 | 920 |

| Max. Turning Length* | mm | 1000 | 1000 | 1000 | 1250 | 1250 | 1250 | 2000 | 2000 | 2000 | 1250 | 1250 | 3000 | 3000 |

| Slides | ||||||||||||||

| X-Axis Travel (Cross) | mm | 360 | 360 | 360 | 410 | 410 | 410 | 410 | 410 | 410 | 480 | 480 | 480 | 480 |

| Z-Axis Travel (Longitudinal) | mm | 1000 | 1000 | 1000 | 1250 | 1250 | 1250 | 2000 | 2000 | 2000 | 1250 | 1250 | 3100 | 3100 |

| Rapid Feed (X & Z Axis) | m/min | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24/20 | 24/20 |

| Main Spindle | ||||||||||||||

| Spindle Motor Power - Fanuc | kW | 22/18.5 | 26/22 | 37/30 | 22/18.5 | 26/22 | 37/30 | 22/18.5 | 26/22 | 37/30 | 26/22 | 37/30 | 26/22 | 37/30 |

| Spindle Motor Power - Siemens | kW | 27.8/18.5 | 33/22 | 45/30 | 27.8/18.5 | 33/22 | 45/30 | 27.8/18.5 | 33/22 | 45/30 | 33/22 | 45/30 | 33/22 | 45/30 |

| Spindle Speed Range | rpm | 50-2500 | 50-1500 | 50-1200 | 50-2500 | 50-1500 | 50-1200 | 50-2500 | 50-1500 | 50-1200 | 50-1500 | 50-1200 | 50-1500 | 50-1200 |

| Spindle Bore | mm | 80 | 110 | 180 | 80 | 110 | 180 | 80 | 110 | 180 | 110 | 180 | 110 | 180 |

| Spindle Nose | A2-8 | A2-11 | A2-15 | A2-8 | A2-11 | A2-15 | A2-8 | A2-11 | A2-15 | A2-11 | A2-15 | A2-11 | A2-15 | |

| Max. Bar Capacity | mm | 65 | 90 | 90 | 65 | 90 | 90 | 65 | 90 | 90 | 90 | 90 | 90 | 90 |

| Turret | ||||||||||||||

| No. of Station | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 12 | |

| Max. Boring Bar Dia. | mm | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 60 | 60 | 60 |

| Tool Size (Cross Sectional) | mm | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 | 32 X 32 |

| Tail Stock | ||||||||||||||

| Quill Dia. | mm | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 170 | 170 | 170 | 170 |

| Quill Stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 200 | 200 | 200 | 200 |

| Thrust (Adjustable) | kgf (Max.) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1500 | 1500 | 1500 | 1500 |

| Accuracy (As per VDI/DGQ 3441) | ||||||||||||||

| Positioning Uncertainty (P) (X / Z Axis) | mm | 0.01 | 0.01 | 0.01 | 0.01/0.015 | 0.01/0.015 | 0.01/0.015 | 0.01/0.02 | 0.01/0.02 | 0.01/0.02 | 0.01/0.015 | 0.01/0.015 | 0.01/0.02 | 0.01/0.02 |

| Repeatability (Ps medium) (X / Z Axis) | mm | 0.005 | 0.005 | 0.005 | 0.005/0.007 | 0.005/0.007 | 0.005/0.007 | 0.005/0.008 | 0.005/0.008 | 0.005/0.008 | 0.005/0.007 | 0.005/0.007 | 0.005/0.008 | 0.005/0.008 |

| Other Data | ||||||||||||||

| Machine Weight # (Approx.) | Kg | 9500 | 9500 | 9500 | 10000 | 10000 | 10000 | 12500 | 12500 | 12500 | 19500 | 19500 | 24000 | 24000 |

| Machine Dimension # (Approx.) | ||||||||||||||

| Length | mm | 5500 | 5500 | 5500 | 5875 | 5875 | 5875 | 6930 | 6930 | 6930 | 7175 | 7175 | 9120 | 9120 |

| Width | mm | 2860 | 2860 | 2860 | 2860 | 2860 | 2860 | 2940 | 2940 | 2940 | 4420 | 4420 | 4420 | 4420 |

| Height | mm | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2900 | 2900 | 2900 | 2900 |

* Depend upon clamping arrangement, Tooling & Job

# Refer machine detailed layout