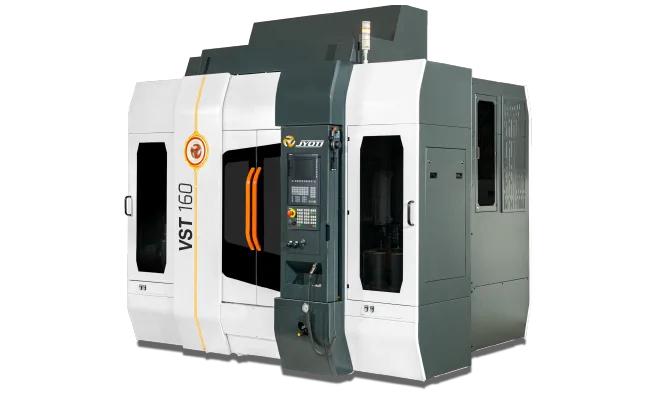

VST

Key Features

- Siemens 828D & Fanuc 0i TF Plus CNC Controller

- Linear Glass Scale

- Job Feeder with 12+12=24 Pallets

- Twin Turret 9 Station

- Chip Conveyor Rear

- Digital Tailstock

- Auto & Manual Coolant Systemn

- Centralized Programmable Lubrication

- Roller Type Linear Motion Guideways

- Electrical Cabinet with Controlled Temperature

- Tool Life Management

| Capacity | VST 160 | |

| Max. Turning Lenght* | mm | 625 |

| Std. Turning Dia. (with gripper) | mm | 65 |

| Max. Job Dia.** | mm | 200 |

| Max. Turning Dia.* | mm | 125 |

| Slides | ||

| X-Axis Travel (Cross) | mm | 240 |

| Z-Axis Travel (Longitudinal) | mm | 625 |

| Feed | ||

| Rapid Feed (X/Y/Z Axis) | m/min | 20 |

| Cutting feed | m/min | 10 |

| Main Spindle | ||

| Spindle Speed | rpm | 5000 |

| Spindle Motor Power | kW | 22 |

| Spindle Nose | A26 | |

| C Axis Resolution | Deg. | 0.001° |

| Turret | ||

| No. of Turret [station] | Nos. | 9+9 |

| Tool holder type | BMT 55 | |

| Auto Loader | ||

| Input Feeder | Nos. | 12 |

| Output Feeder | Nos. | 12 |

| Max. Possible Job Weight | kg | 8.5 |

| Accuracy (As per VDI/DGQ 3441) | ||

| Positioning Uncertainty (P) | mm | 0.01 |

| Repeatability (Ps medium) | mm | 0.005 |

| Other | ||

| Machine Weight #(Approx.) | kg | 8700 |

| Machine Dimension # (Approx.) | ||

| Length | mm | 4250 |

| Width | mm | 3050 |

| Height | mm | 3000 |

* Depend upon clamping arrangement, Tooling & Job

# Refer machine detailed layout