TAC

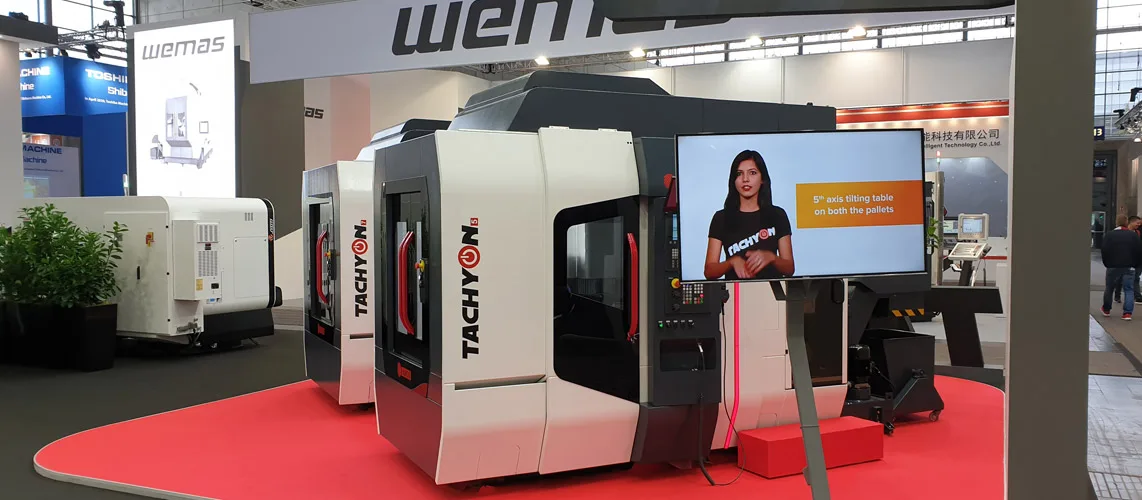

Key Features

- Optimized Construction to support 60 m/min rapid rates.

- High acceleration up-to 15 m/sec²

- Roller type high precision linear motion guideways.

- Directly coupled high speed BT-30 spindle.

- Integral work-piece changer (APC) with changing time is 4 sec.

- 16 tool drum type ATC with tool changing time 1 sec.

- Hyd. fixture & Rotary production system available.

- 90° tilting operating panel to view machining area.

- Ergonomic design and aesthetic look.

- Efficient chip removal and easy disposal.

- Auto & manual coolant.

- Centralized & programmable lubrication.

Customer Testimonial

- High Speed Machine

- Productivity Solutions

- 90° tilting operating panel

- Automatic Pallet Changer

- Fast ATC

- TPM Friendliness

Fragrance in Favor !!

To celebrate the maiden success of the Tachyon series of CNC High Dynamic Drill Tap Centers at IMTEX'17

the symbolic fragrance "TACHYON" was launched by the worthy hands of

Ms. Sonali Kulkarni

President, Fanuc, India.

This pleasing floral aroma will always cherish the sweet memory of inception journey of this world class product range Tachyon. This fragrance was developed through the essence of the exotic rare spices of wild flowers from Himalayas

| Tachyon 4 | Tachyon 5 | Tachyon 7 | ||

| Capacity | ||||

| X-Axis Travel | mm | 400 | 550 | 750 |

| Y-Axis Travel | mm | 400 | 400 | 400 |

| Z-Axis Travel | mm | 450 | 450 | 450 |

| Dis. From Spindle Face to Table Top (Min.-Max.) | mm | 200-650 | 200-650 | 200-650 |

| Automatic Pallet Changer | ||||

| Table Size | mm | 560 x 400 | 600 x 400 | 800 x 400 |

| T-Slot Dimention | mm | 4 x 14 x 100 | 4 x 14 x 100 | 4 x 14 x 100 |

| Dist. from Floor to Table | mm | 804 | 804 | 804 |

| Max. Load on Table | kgf | 200 x 2 | 250 x 2 | 300 x 2 |

| Main Spindle | ||||

| Spindle Speed | rpm | 10000 | 10000 | 10000 |

| Spindle Motor Power -Siemens | kW | 20.4/4.8 | 20.4/4.8 | 20.4/4.8 |

| Spindle Nose | mm | BT 30 (BBT 30) | BT 30 (BBT 30) | BT 30 (BBT 30) |

| Feed | ||||

| Rapid Traverse (X/Y/Z Axis) | m/min | 70/60/60 | 70/60/60 | 70/60/60 |

| Cutting Feed | m/min | 30 | 30 | 30 |

| Automatic Tool Changer | ||||

| No. of Tool | 16 | 16 | 16 | |

| Max. Tool Dia. | mm | 80 | 80 | 80 |

| Max.Tool Length | mm | 200 | 200 | 200 |

| Max.Tool Weight | Kg | 3 | 3 | 3 |

| Accuracy (As per VDI/DGQ 3441) | ||||

| Positioning Uncertainty (P) | mm | 0.01 | 0.01 | 0.01 |

| Repeatability (Ps medium) | mm | 0.005 | 0.005 | 0.005 |

| Other Data | ||||

| Machine Weight #(Approx.) | Kg | 4200 | 4500 | 4800 |

| Machine Dimension #(Approx.) | ||||

| Length | mm | 3480 | 3480 | 3480 |

| Width | mm | 1400 | 1620 | 1740 |

| Height | mm | 2630 | 2630 | 2630 |

* Depend upon clamping arrangement, Tooling & Job

# Refer machine detailed layout