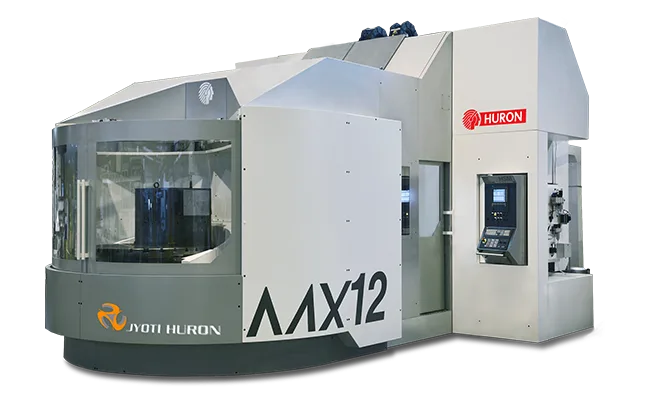

MX

Key Features

- High speed & high precision 5-axis mill-turn machine.

- Mobile column extreme rigid structure.

- Harmonically stable machine.

- Rotary table with direct driven torque motor.

- Swiveling head of -45° /+ 180°.

- Two position head vertical & horizontal.

- Powerful electro-spindle with high torque.

- Fork type head available for negative angle machining.

- High rapid of 40 m/min

- Faster automatic work piece changer.

- Roller types L.M. guideways with linear glass scale

- Large accessibility from top for loading/unloading.

- Efficient chip flow and effective chip evacuation.

- Electrical with quality device & panel AC.

- Auto & manual coolant.

- Centralized & programmable lubrication.

- Simultaneous 5-axis Machining

- High Speed Machining

- Automatic Pallet Changer

- TRIM Table

- High Speed Electro Spindle

| Linear Axis X/Y/Z | MX 8 [M] | MX 8 [MT] | MX 10 [M] | MX 10 [MT] | MX 11 [M] | MX 12 [M] | MX 12 [MT] | MX 12L [M] | MX 12L [MT] | MX 16 [M] | MX 16 [MT] | MX 20 [M] | MX 20 [MT] | |

| Travels | mm | 1160 x 1000 x 900 | 1200 x 1200 x 1000 | 1250 x 1250 x 1000 | 1200 x 1600 x 1000 | 2000 x 1600 x 1100 | 2300 x 2300 x 1250 | 3000 x 3100 x 1600 | ||||||

| Rapid Feed Rates | m/min | 40 | 40 | 60 | 40 | 40 | 40 | 20 | ||||||

| Acceleration on Axis | m/s² | 4 | 4 | 4 | 4 | 4 | 3 | 1.8 / 2 / 2 | ||||||

| Rotating Axis A - Head | ||||||||||||||

| Rotating Speed | rpm | 100 | 100 | 30 | 100 | 100 | 100 | 100 | ||||||

| Torque : Clamping / Motor | Nm | 2500/2120 | 2500/2120 | 7000/2660 | 2500/2120 | 2500/2120 | 7000/3640 | 7000/3640 | ||||||

| Rotating Axis C - Table | ||||||||||||||

| Rotating Speed | rpm | 50 | 500 | 65 | 500 | 30 | 50 | 250 | 50 | 250 | 9 | 250 | 7 | 120 |

| Area | mm | Ø 1000 x 800 | Ø 800 | Ø 1250 x 900 | Ø 1000 | Ø 1250 x 1100 | Ø 1600 x 1250 | Ø 1400 | Ø 1600 x 1250 | Ø 1400 | Ø 1750 | Ø 1250 | Ø 2200 | Ø2200 |

| Admissible Load | kg | 2000 | 2000 | 2500 | 2500 | 2500 | 4000 | 4000 | 4000 | 4000 | 10000 | 5000 | 12000 | 10000 |

| Spindle | ||||||||||||||

| Rotating Speed | rpm | 15000 | 10000 | 15000 | 10000 | 10000 | 15000 | 10000 | 15000 | 10000 | 10000 | 10000 | ||

| Taper | HSK 63A | HSK 100A | HSK 63A | HSK 100A | HSK 100A | HSK 63A | HSK 100A | HSK 63A | HSK 100A | HSK 100A | HSK 100A | |||

| Power | kW | 29 | 43/33 | 29 | 43/33 | 43/33 | 29 | 43/33 | 29 | 43/33 | 43/33 | 43/33 | ||

| Torque (S6-40% / S1) | Nm | 277 | 415/313 | 277 | 415/313 | 415/313 | 277 | 415/313 | 277 | 415/313 | 415/313 | 415/313 | ||

| Characteristic Speed | rpm | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | ||

| Accuracy | Linear Axis | Rotating Axis | Linear Axis | Rotating Axis | ||||||||||

| Uncertainty P | 7 µ | 10 sec | 7 µ | 10 sec | ||||||||||

| Repeatability : Ps Medium | 4 µ | 5 sec | 4 µ | 5 sec | ||||||||||

| Tool Magazine | ||||||||||||||

| Pockets Quantity | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |||

| Taper | HSK 63A | HSK 100A | HSK 63A | HSK 100A | HSK 100A | HSK 63A | HSK 100A | HSK 63A | HSK 100A | HSK 100A | HSK 100A | |||

| Tool Length | mm | 400 | 500 | 400 | 650 | 650 | 400 | 650 | 400 | 650 | 400 | 400 | ||

| Tool Diameter (All/Adj.Empty) | Ø (mm) | 95/120 | 125/250 | 95/120 | 125/250 | 125/250 | 95/120 | 125/250 | 95 / 120 | 125/250 | 120 | 120 | ||

| Max. Tool Weight | kg | 8 | 25 | 8 | 25 | 25 | 8 | 25 | 8 | 25 | 10 | 10 | ||

| Coolant | ||||||||||||||

| Flow - Pressure | lpm - bar | 30 - 5 | 60 - 5 | 60 - 5 | 30 - 5 | 30 - 5 | ||||||||

| Tank | ltr | 700 | 1500 | 1500 | 1500 | 1500 | ||||||||

* Depend upon clamping arrangement, Tooling & Job

# Refer machine detailed layout