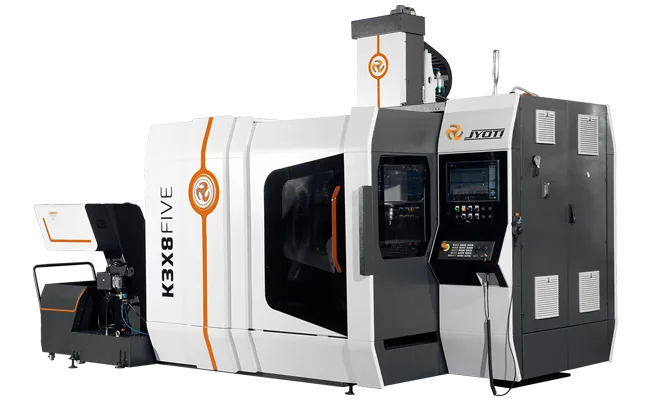

KX Five

Key Features

- Structure with fixed portal in ribbed cast iron with stiffness wall.

- Harmonically stable Machine for complex part machining.

- A & C axis TRIM table with high torque capacity.

- 20° negative angle in table for 6th side machining.

- Large accessibility from the top for better approach.

- Incremental measurement by optical encoders.

- High speed 24000rpm electro-spindle.

- Multiple variant in palletization up to 6 pallets.

- 20 tool fast auto tool changer.

- Efficient chip disposal and easy chip evacuation.

- Electrical with quality device & panel AC.

- Ergonomic design and aesthetic look.

- Auto & manual coolant.

- Centralized & programmable lubrication.

- High Speed Machine

- Simultaneous 5-Axis Machine

- Rotary Table with TRIM

- High Speed Electro Spindle

| Linear Axis (X,Y & Z Axis) | K3X8 Five | K2X10 Five | |

| Travels | mm | 780 x 700 x 500 | 900 x 900 x 500 |

| Rapid Feedrates | m/min | 50 | 50 |

| Acceleration on axis | m/sec2 | 5 | 5 |

| Structure | Table on a 55˚ plane | Table on a 45˚ plane | |

| Tilting Axis - A | +30° / - 180° | +45° / - 180° | |

| Rotation Speed A - Axis | rpm | 50 | 40 |

| Rotational Axis - C | 360° | 360° | |

| Rotation Speed C - Axis | rpm | 50 | 50 |

| Working Position | Horizontal Position = 0 | Horizontal Position = 0 | |

| (Angle Spindle Axis/Table) | Vertical Position = 90° Inclined= -20° | Vertical Position =90° Inclined= -20° | |

| Table | |||

| Table Area | mm | Ø500 | Ø630 |

| Admissible Load on Table | kg | 250 | 500 |

| Distance from spindle nose to table top | mm | 525 | 700 |

| Spindle | |||

| Rotating Speed | rpm | 18000 | 18000 |

| Tool Taper | HSK 63A | HSK 63A | |

| Power - Torque (S6-40% / S1) | kW-Nm | 26.7 - 110/84 | 26.7 - 110/84 |

| Characteristics Speed | rpm | 3400 | 3400 |

| Tool Magazine | |||

| Pocket Quantity | 36 | 36 | |

| Max. Tool Length | mm | 250 | 300 |

| Tool Diameter | mm | 90 | 90 |

| Max. Tool Weight | kg | 10 | 10 |

| Accuracies | |||

| Uncertainty : P | Linear axes X-Y-Z: 4µm - Rotating axes A - C: 7.2 Sec | ||

| Repetability : Ps Medium | Linear axes X-Y-Z: 2µm - Rotating axes A - C: 3.6 Sec | ||

| Coolant | |||

| Flow -Pressure | l/min-bar | 30-3 | 30-3 |

| Tank | Liters | 230 | 230 |

| Over-all Dimension | |||

| Length/Width/Height | mm | 2690/4710/3320 | 3510/4910/3470 |

| Machine Weight | kg | 10000 | 14500 |

* Depend upon clamping arrangement, Tooling & Job

# Refer machine detailed layout