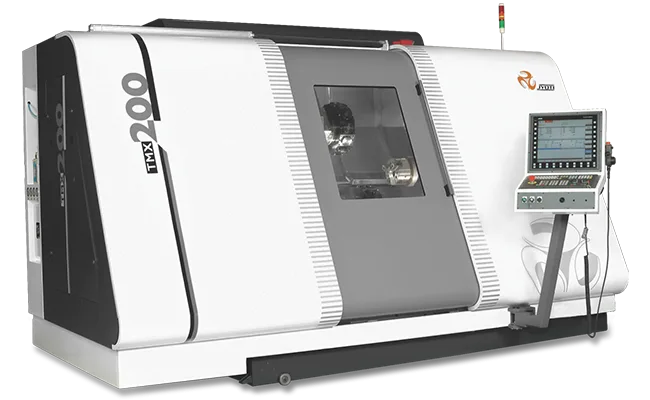

TMX

Key Features

- Single piece slant bed structure.

- 3-axis in upper turret & 2-axis in lower turret.

- Main & secondary high torque electro-spindle.

- High rapid rate allow up-to 30m/min

- Complex part machining in single setup.

- High precision linear motion guideways

- Liner Glass scale on all axis.

- High speed electro spindle with C-axis and rigid headstock.

- Directly coupled and precision linear axis.

- Ergonomic designed.

- Hydraulic chucking for both spindles.

- Auto and manual coolant system.

- Electrical with quality devices & panel with A.C.

- Centralized & programmable lubrication.

- High speed machine

- Electro-spindle

- TPM Concept

| TMX 200 | |||

| Capacity | |||

| Swing Over Bed | mm | 600 | |

| Std. Turning Dia. | mm | 250 | |

| Maximum Turning Length * | mm | 725 | |

| Travels | |||

| X1/Y/Z1 Axis | mm | 300/±40/750 | |

| X2/Z2/Z3 Axis | mm | 180/750/770 | |

| Rapid Feed | |||

| X1/Y/Z1 Axis | m/min | 25/15/30 | |

| X2/Z2/Z3 Axis | m/min | 25/30/30 | |

| Electro Spindle | Main | Secondary | |

| Spindle Motor Speed | rpm | 50-4000 | 50-4000 |

| Spindle Nose | A2-6 | A2-6 | |

| Spindle Bore | mm | 65 | - |

| Spindle Motor Power | kW | 27/21 | 27/21 |

| Spindle Motor Torque | Nm | 255/200 | 255/200 |

| Max.Bar Capacity | mm | 52 | - |

| C-Axis Angular Resolution | deg | 0.0001 | 0.0001 |

| Turret | Upper | Lower | |

| Number of Driven Station | 12 | 12 | |

| Drive Tool Holder | VDI 40 | VDI 40 | |

| Max.Live Tool Speed | rpm | 50-4000 | 50-4000 |

| Max.Boring Bar Dia. | mm | 40 | 40 |

| Live Tool Motor Power | kW | 4.8 | 4.8 |

| Live Tool Torque | Nm | 13 | 13 |

| Accuracy (As per VDI/DGQ 3441) | |||

| Positioning Uncertainty (P) : X/Z/Y Axis | mm | 0.008/0.012/0.008 | |

| Repeatability (Ps medium) : X/Z/Y Axis | mm | 0.005/0.005/0.005 | |

| Other Data | |||

| Machine Weight # (Approx.) | kg | 10500 | |

| Machine Dimension # (Approx.) | |||

| Length | mm | 5740 | |

| Width | mm | 2725 | |

| Height | mm | 2600 |

* Depend upon clamping arrangement, Tooling & Job

# Refer machine detailed layout