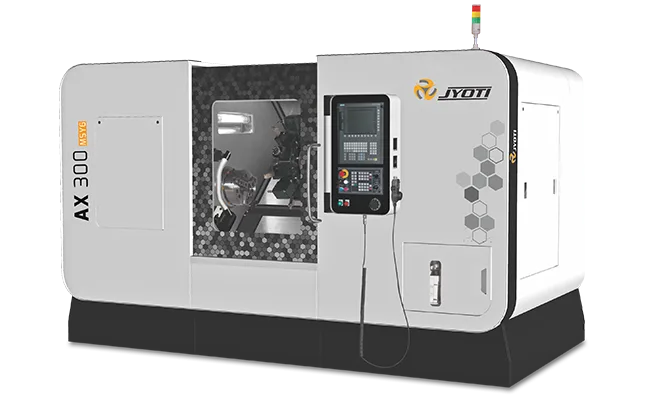

AX

Key Features

- Unique single piece slant bed construction.

- 12-station live tool turret with independent Y axis.

- High speed electro spindle with C-axis and rigid headstock.

- Secondary spindle available.

- High rapid rates upto 35 m/min with higher acceleration

- Directly Coupled and precision linear axis.

- Ergonomic designed, improved operating condition and aesthetic look.

- Hydraulic chucking.

- Efficient chip flow and easy chip handling.

- Auto and manual coolant system.

- Electrical with quality devices & panel with A.C.

- Centralized & programmable lubrication.

- Monoblock Rigid Structure

- Electro-spindle

- TPM Concept

| AX 200 | AX 200M | AX 200MY | AX 200MSY | AX 300 | AX 300M | AX 300MY | AX 300MSY | ||

| Capacity | |||||||||

| Swing Over Bed | mm | 550 | 550 | 550 | 550 | 650 | 650 | 650 | 650 |

| Std. Turning Dia. | mm | 370 | 330 | 330 | 330 | 465 | 420 | 420 | 420 |

| Max. Turning Dia.* | mm | 370 | 330 | 330 | 330 | 480 | 420 | 420 | 420 |

| Maximum Turning Length * | mm | 325/625 | 325/625 | 325/625 | 625 | 600/1200 | 600/1200 | 600/1200 | 600 |

| Chuck Dia. | mm | 200 | 200 | 200 | 200 | 250 | 250 | 250 | 250 |

| Slides | |||||||||

| X-Axis Travel | mm | 200 | 200 | 200 | 200 | 250 | 250 | 250 | 250 |

| Y-Axis Travel | mm | NA | NA | ±40 | ±40 | NA | NA | ±50 | ±50 |

| Z-Axis Travel | mm | 325/625 | 325/625 | 325/625 | 625 | 625/1225 | 625/1225 | 625/1225 | 625 |

| Rapid Feed (X,Y & Z- axis) | m/min | 24/NA/30 | 24/NA/30 | 24/24/30 | 24/24/30 | 24/NA/30 | 24/NA/30 | 24/24/30 | 24/24/30 |

| Main Spindle (Motorised) | |||||||||

| Spindle Motor Power (Cont)Siemens- Fanuc | kW | 9.15 | 9.15 | 9.15 | 9.15 | 20 | 20 | 20 | 20 |

| Spindle Speed Range | rpm | 4500 | 4500 | 4500 | 4500 | 4000 | 4000 | 4000 | 4000 |

| Spindle Nose | A26 | A26 | A26 | A26 | A28 | A28 | A28 | A28 | |

| Max. Bar Capacity | mm | 52 | 52 | 52 | 52 | 65 | 65 | 65 | 65 |

| Sub-Spindle (Motorised) | |||||||||

| Spindle Motor Power (Cont)Siemens- Fanuc | kW | NA | NA | NA | 7.5 | NA | NA | NA | 9.15 |

| Spindle Speed Range | rpm | NA | NA | NA | 5000 | NA | NA | NA | 4500 |

| Spindle Nose | NA | NA | NA | A25 | NA | NA | NA | A26 | |

| Spindle Travel | mm | NA | NA | NA | 630 | NA | NA | NA | 620 |

| Turret | |||||||||

| Turret Type | Servo | Live | Live | Live | Servo | Live | Live | Live | |

| Number of Station | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

| Max. Boring Bar Dia. | mm | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 |

| Tool Size (Cross Sectional) | mm | 25 x 25 | 25 x 25 | 25 x 25 | 25 x 25 | 25 x 25 | 25 x 25 | 25 x 25 | 25 x 25 |

| Live Tool Power (Siemens/Fanuc) | kW | NA | 4.8/4.5 | 4.8/4.5 | 4.8/4.5 | NA | 4.8/5.5 | 4.8/5.5 | 4.8/5.5 |

| Live Tool Speed (Siemens) | rpm | NA | 4500 | 4500 | 4500 | NA | 4500 | 4500 | 4500 |

| Live Tool Speed (Fanuc) | rpm | NA | 4500 | 4500 | 4500 | NA | 3000 | 3000 | 3000 |

| Live Tool Type | NA | VDI30/BMT45 | VDI30/BMT45 | VDI30/BMT45 | NA | VDI40/BMT55 | VDI40/BMT55 | VDI40/BMT55 | |

| Tail Stock | |||||||||

| Tailstock Type | Digital | Digital | Digital | NA | Digital | Digital | Digital | NA | |

| Tailstock Travel | mm | 330/630 | 330/630 | 330/630 | NA | 620/1220 | 620/1220 | 620/1220 | NA |

| Live Quill Taper | MT-5 | MT-5 | MT-5 | NA | MT-5 | MT-5 | MT-5 | NA | |

| Quill Dia. | mm | 130 | 130 | 130 | NA | 130 | 130 | 130 | NA |

| Thrust | kgf | 350 | 350 | 350 | NA | 500 | 500 | 500 | NA |

| Accuracy (As per VDI/DGQ 3441) | |||||||||

| Positioning Uncertainty (P) | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| Repeatability (Ps medium) | mm | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 |

| Machine Weight # (Approx.) | kg | 4100/4500 | 4200/4600 | 4400/4800 | 5000 | 6300/6900 | 6500/7100 | 6500/7100 | 6700 |

| Machine Dimension # (Approx.) | |||||||||

| Length | mm | 2610/2910 | 2610/2910 | 2610/2910 | 3220 | 3490/4090 | 3490/4090 | 3490/4090 | 3490 |

| Width | mm | 1735 | 1735 | 1735 | 1735 | 2000 | 2000 | 2000 | 2000 |

| Height | mm | 1960 | 1960 | 1960 | 1960 | 2205 | 2205 | 2205 | 2205 |

* Depend upon clamping arrangement, Tooling & Job

# Refer machine detailed layout